How to understand the magnetic levitation blower in detail

Magnetic levitation blower is a kind of turbine with magnetic levitation bearing.

The main structure is that the blower impeller is directly installed on the extended end of the motor shaft, and the rotor is vertically suspended on the active magnetic bearing controller. It does not need speed increaser and coupling to realize direct drive by high-speed motor.

The core of the single-stage high-speed centrifugal blower regulated by frequency converter is the technology of magnetic bearing and permanent magnet motor.

(1) High efficiency impeller: the high efficiency impeller is designed with three-dimensional flow, and the five axis machining technology ensures the manufacturing accuracy of the impeller.

(2) Magnetic bearing: no mechanical wear, low energy, semi permanent life.

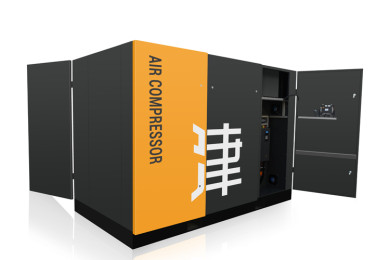

(3) Structural design integration: the fan impeller is directly installed at the shaft end of the motor, integrated with the control system, and packaged in the box, with simple and concise structure.

(4) Convenient installation and maintenance: no lifting equipment and large space, no special foundation, convenient maintenance, and save the capital construction cost of the machine room.

(5) Modular design of the system: according to different user flows, multiple blowers are allowed to work in parallel, with wide adjustment range and strong flexibility.