- Tianjin Jinjing Gas Compressor Manufacturing Co.,Ltd.

- Get a quote

News Group

Air Compressor Knowledge

- Maintenance instructions for mobile diesel rotary screw truck air compressor1. Check the air filter of the mobile diesel rotary screw truck air compressor every 500 working hours and replace it every 1000 working hours.To prevent air filter clogging and maximize air compressor performance, it is important to inspect the air filter regularly to check for dust, debris and other particles that can reduce the efficiency of the compressor. After changing the air filter, it is recommended to clean the filter housing and check for other signs of damage.Feb 26,2023

- how to adjust air compressor pressure switch1. Turn off the main power switch to your air compressor. Wait for all of the air inside the compressor's tank to empty.Feb 25,2023

2. Locate the air compressor pressure switch. It should be mounted near the top of the air compressor.

3. - Precautions for maintenance and operation of permanent magnet frequency conversion air compressorThe permanent magnet frequency conversion air compressor is widely used in various industries due to its advantages of high efficiency and energy saving. However, the maintenance and operation of the permanent magnet frequency conversion air compressor must be taken seriously to ensure its safe, efficient and reliable operation. This article will discuss some precautions for the maintenance and operation of permanent magnet frequency conversion air compressor.Feb 17,2023

- what size air compressor do i need?Air compressors are a versatile tool used in a variety of applications. From home repairs to industrial operations, air compressors can be found in many different sizes and types. Choosing the right one for the job can be a daunting task, but with a few guidelines, you can find the perfect air compressor for any job.Feb 17,2023

- The causes and solutions of air compressor shutdown failure caused by low air compressor exhaust pressureCause #1: OverheatingFeb 10,2023

The most common cause of air compressor shutdown failure due to low exhaust pressure is overheating. When an air compressor is used for extended periods of time, the motor and other components can become extremely hot. If the temperature inside the air compressor gets too high, the low pressure switch may shut off the air compressor to avoid further damage. If this occurs, you will likely notice that the unit has shut down due to a lack of exhaust pressure. - Effect of air compressor oil temperature on equipmentAs an essential part of an air compressor, oil is an integral part of its performance and helps to keep the machine and its components running smoothly over the long term. Additionally, air compressor oil temperature can have a large impact on how well the system functions, and therefore it is important to understand the influence of oil temperature on the performance of your equipment.Feb 10,2023

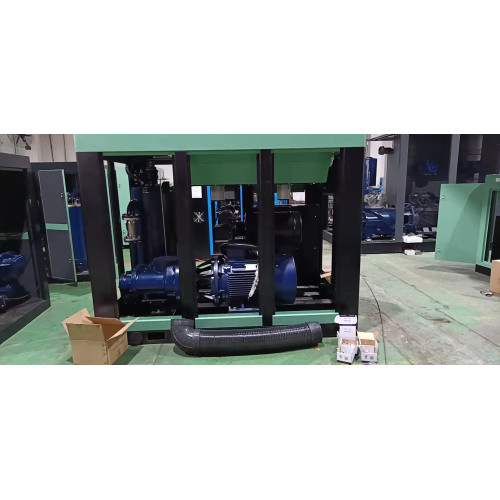

- Technical performance characteristics of rotary screw compressorRotary Screw Compressor technology is a highly reliable and efficient type of air compressor that is commonly used in industrial and manufacturing applications. In fact, rotary screw compressor technology can be found in applications ranging for industrial field.Feb 3,2023

- Explain in detail the advantages and application environment of screw air compressorAdvantages of Screw Air Compressors:Feb 2,2023

-Efficiency: Screw air compressors are much more efficient than piston compressors, as they require less energy to operate and produce more compressed air.

-Quieter Operation: Screw air compressors are also much quieter than piston air compressors, making them ideal for applications where noise levels are an issue. - The product characteristics, applicable environment and production process requirements of the VSD variable frequency screw air compressorProduct Characteristics:Feb 2,2023

VSD variable frequency screw air compressor is a type of energy-saving air compressor which uses a variable frequency drive (VFD) to regulate the speed of the motor and compressor. This allows the compressor to adjust its speed according to the compressed air needs. This results in a lower power consumption and increased efficiency, as well as improved air quality and longer service life. - The difference between piston air compressor and screw air compressorPiston air compressors and screw air compressors are two of the most common types of air compressors used in industrial applications. Both types of compressors are used to compress air and provide compressed air to power various tools, but they work in different ways and have different advantages and disadvantages.Feb 1,2023